The glass bead used in shot blasting duties constitutes an abrasive

As glass beads are spherical and without edges and rims it does not pull off the covering and metal base as if it were a cutting tool. For that reason shot blasting with glass beads is still admitted in those cases in which strict dimensional tolerances should be kept.

1.Decorative finishing

The superficial appearance achieved by shot blasting with glass beads on steel, aluminium, stainless steel, brass, tin, acrylic, plastic, etc, is really unique, obtaining a dull finishing that valorises the piece.

2.Engravings

The engraving that is performed by means of shot blasting is obtained by the difference between the zones that have not been treated (shinny) and the zones that have been shot blasted (dull). These engravings are generally performed with masks made especially for this purpose and although it can also be done with other abrasives, glass beads ensure excellent finishing and also a much longer lifetime of the masks used, due to the minimum abrasiveness of this material.

3.Shot peening

It is the effect of a flow of spherical particles shot at great speed on a metallic surface compacting it. This hammering action (peening) causes crushing of the surface due to the plastic deformation that induces compression tensions parallel to the surface, that generally extend from 5 to 10 mils (a thousandth of an inch) of depth.

TYPICAL CHEMICAL ANALISIS [%]:

| SiO2 | Na2O | Fe2O3 | Al2O3 | MgO | CaO | Other |

| ≥65.0% | ≤14.0% | ≥0.15% | 0.5-2.0% | ≥2.5% | ≤8.0% | 2.0% |

PHYSICAL PROPERTIES:

| Bulk Density | Real Density | Mohs Hardness | HRC hardness | Roundness | Magnetic |

| 1.5g/cm3 | 2.5g/cm3 | 6-7 | 46 | ≥80.0% | ≤0.1% |

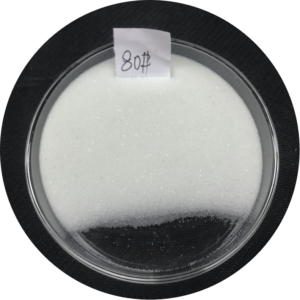

AVAILABLE SIZES

| Sandblasting | 20# 30# 40# 50# 60# 70# 80# 90# 100# 120# 140# 150# 170# 180# 200# 220# 240# 325# |

| Grinding | 0.8-1mm 1-1.5mm 1.5-2mm 2-2.5mm 2.5-3mm 3.5-4mm 4-4.5mm 4-5mm 5-6mm 6-7mm |

| Road Marking | BS6088A BS6088B EN1424 EN1423 AASHTO TYPE1 AASHTO TYPEII JIS NO.1 JIS NO.2 |