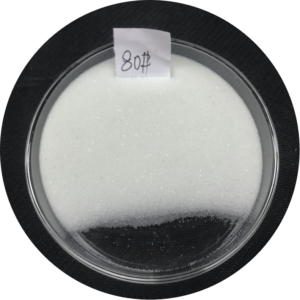

Glass bead is a commonly used abrasive media in blast cleaning. Depending on the size used and when used correctly, it can create an aesthetic, smooth finish, be used for NDT Blast Preparations or even to delicately provide a clean surface free from corrosion or contamination, without significantly impacting the shape or impinging into the surface that is being treated.

Long-Lasting And Environmentally Friendly

Being able to re-use a blast media is an important way to reduce costs, as well as helping to protect the environment.

Glass bead can typically be recycled up to 6 times (subject to client approval) before their effectiveness reduces, lessening the need to renew the media with each surface treatment and cutting down the amount of waste that is generated.

The beads are typically manufactured from recycled glass and are inert, lowering your business’s carbon footprint.

Safe For Operatives

Unlike silica sand, glass bead does not contain silica, making it a safer alternative for blast operatives. With bead blasting, concerns over the long-term health effects, particularly on the respiratory system, are reduced.

Non-Reactive With Other Chemicals

With glass bead being chemically inert,the glass bead blasting is a reliable and flexible solution in industrial situations.

More Information

Glass bead blasting is a highly effective, versatile, and affordable option that can produce an aesthetic finish alone