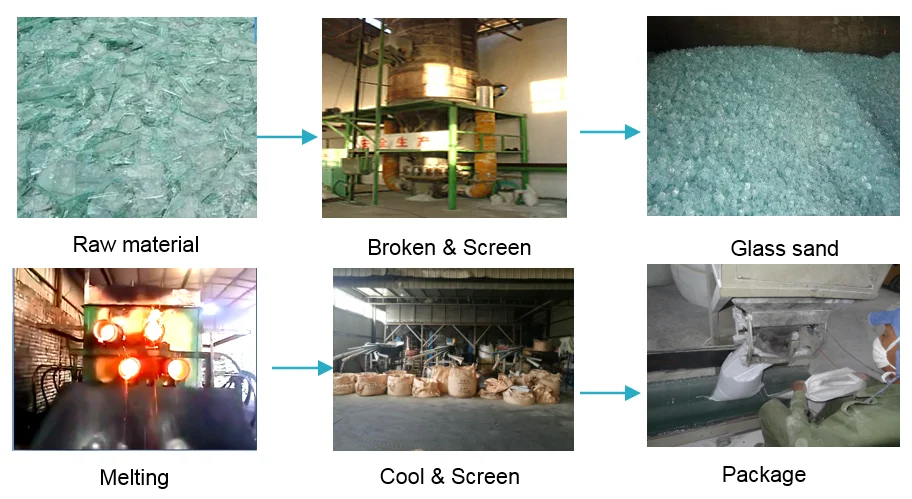

Glass beads are made of broken glass, flat glass and other raw materials by high temperature melting bead processing. Low thermal conductivity, high strength, good chemical stability, and the texture of glass beads themselves, glass beads instead of plastic raw materials are widely used in filling, such as gravity blanket filling, compression filling, medical filling, weighted blanket filling, toy filling and so on.

Available size

Sandblasting glass beads | Filling media and abrasives | Road making glass beads |

30-80mesh | 0.4-0.6mm | BSW |

30-50mesh (46mesh) | 0.6-0.8mm | BS 6088 A |

40-60mesh (60mehs) | 0.8-1mm | BS 6088B |

50-70mesh (80mehs) | 0.8-1.2mm | ASTM |

70-100mesh (60mehs) | 1-1.5mm | AASHTO TYPE1 |

100-140mesh (100mehs) | 1.5-2mm | AASHTO TYPE2 |

150-200mesh (180mehs) | 2-2.5mm | EN |

200-250mesh (250mehs) | 2.5-3mm | EN1424 |

250-280mesh (280mehs) | 3-4mm | EN1423 |

28-320mesh (325mesh) | 4-5mm |

|

400mesh | 5-6mm |

|

Application

Glass Beads / Glass Microspheres used as sandblasting materials are with the characteristics of clearness, hardness and toughness. They are manufactured from soda lime silica glass. We could also supply Glass Beads / Glass Microspheres manufactured from borosilicate glass upon requirement. Glass Beads / Glass Microspheres used as blasting materials offers the flexibility to remove many different types of surface imperfections, including burrs, rust, scales, paint removal and so on.

Reflective glass beads is the essential material for the coating of road marking, it is mainly used for road marking. The glass beads for road marking can improve the retro-reflective performance of road surface coating and increase the safety for night driving. When driving at night, the lamp shines on the marking line with glass beads in it, the ray of lamp is reflected back parallel. So the driver can look at the road clearly and drive safely at night.